Return

Email

3M™ Scotchkote™ Fusion-Bonded Epoxy Coating 134WItem is usually in stock, but we'll be in touch if there's a problem

by 3M

3M™ Scotchkote™ Fusion-Bonded Epoxy Coating 134WItem is usually in stock, but we'll be in touch if there's a problem

by 3M

Call for Price

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

3M™ Scotchkote™ Fusion-Bonded Epoxy Coating 134WItem is usually in stock, but we'll be in touch if there's a problem

by 3M

Price:

Call for Price

Part Number: 408AL1H

UPC:

Vendor Item Number: 7100007283

Call for Price

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

Technical Details

Industrial Category:

Paint, Equipment and Supplies

Industrial Subcategory:

Specialty Paints, Coatings, and Additives

Industrial Subtype:

Epoxy, Urethane, and Specialty Coatings

Application:

Oil & Gas: Refining , Oil & Gas: Custom Coating , Oil & Gas: Internal Coatings , Oil & Gas: Factory Applied Pipe Coating , Oil & Gas: Exploration and Pipeline , Utilities & Power: Transmission & Distribution , Oil & Gas: Transportation

Color Family:

Green

Container Volume:

65.0 lb

Coverage Area:

0.66 sq meter per kg per mm (127 sq feet per pound per mil)

Drinking Water Approvals:

NSF/ANSI 61 (Pipes, Fittings, Pumps, & Valves Only)

ECCN:

EAR99

Form:

Powder

Full Cure Time Temperature Time:

120 second gel, 15 minute cure at 204°C (400°F)

Mixed Color:

Forest Green

Product Color:

Green

Product Type:

Internal Coating

Recommended Application:

Pipe

Recommended Surfaces:

Steel

RoHS EU Comments:

Contact 3M for information

Shelf Life:

18.0 mo

Storage Temperature:

Store below 27C (80F)

Manufactured By:

3M

+

Additional Information

- and other service environments

- harsh chemicals and sea water.

- hydrocarbons

- Long-term performance history in water

- Meets the requirements of AWWA Standard C213 and C550

- Resistant to corrosive soils

- sewage

Product Overview

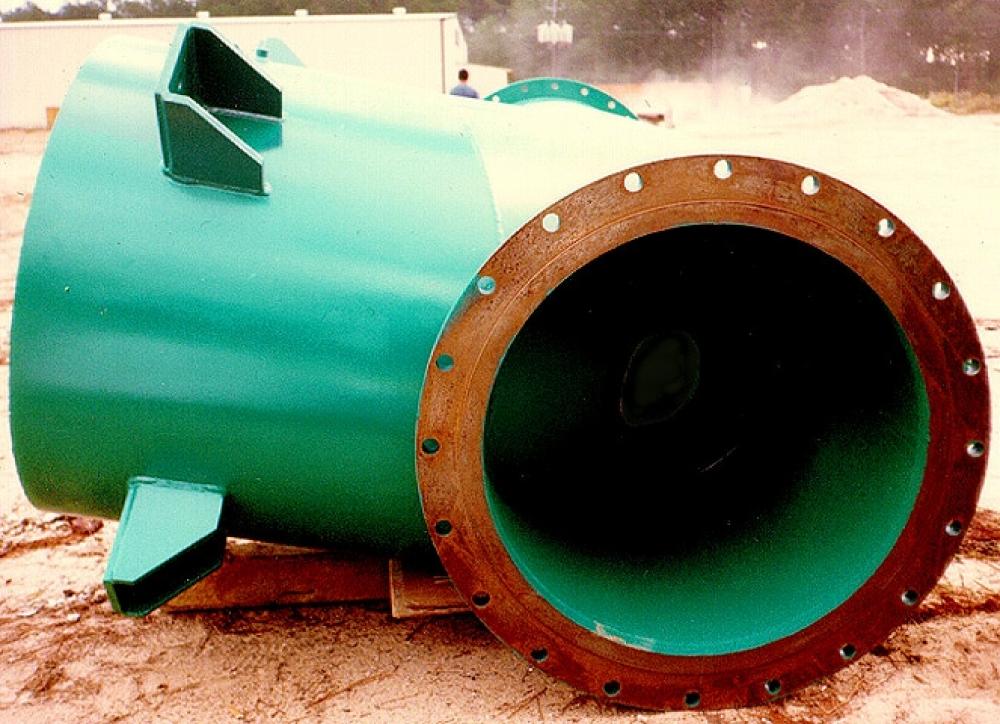

Scotchkote FBE Coating 134W is a baked on epoxy coating that can be custom applied to protect pipelines (external and internal) and a variety of infrastructure components from corrosion. Designed for flock or electrostatic spray application. Due to its long gel time (up to 2.5 minutes at 350ºF/177ºC), large surfaces or parts with complex recesses can be coated without overspray or laminations.3M Scotchkote 134 Fusion-Bonded Epoxy Coating is a one-part, heat curable, thermosetting epoxy coating designed for corrosion protection of metal. The epoxy is applied to preheated steel as a dry powder which melts and cures to a uniform coating thickness. This bonding process provides excellent adhesion and coverage on applications such as valves, pumps, pipe drains, hydrants and porous castings. Scotchkote 134 coating is resistant to wastewater, corrosive soils, hydrocarbons, harsh chemicals, and sea water. Powder properties allow easy manual or automatic application by electrostatic or air-spray equipment.