Return

Email

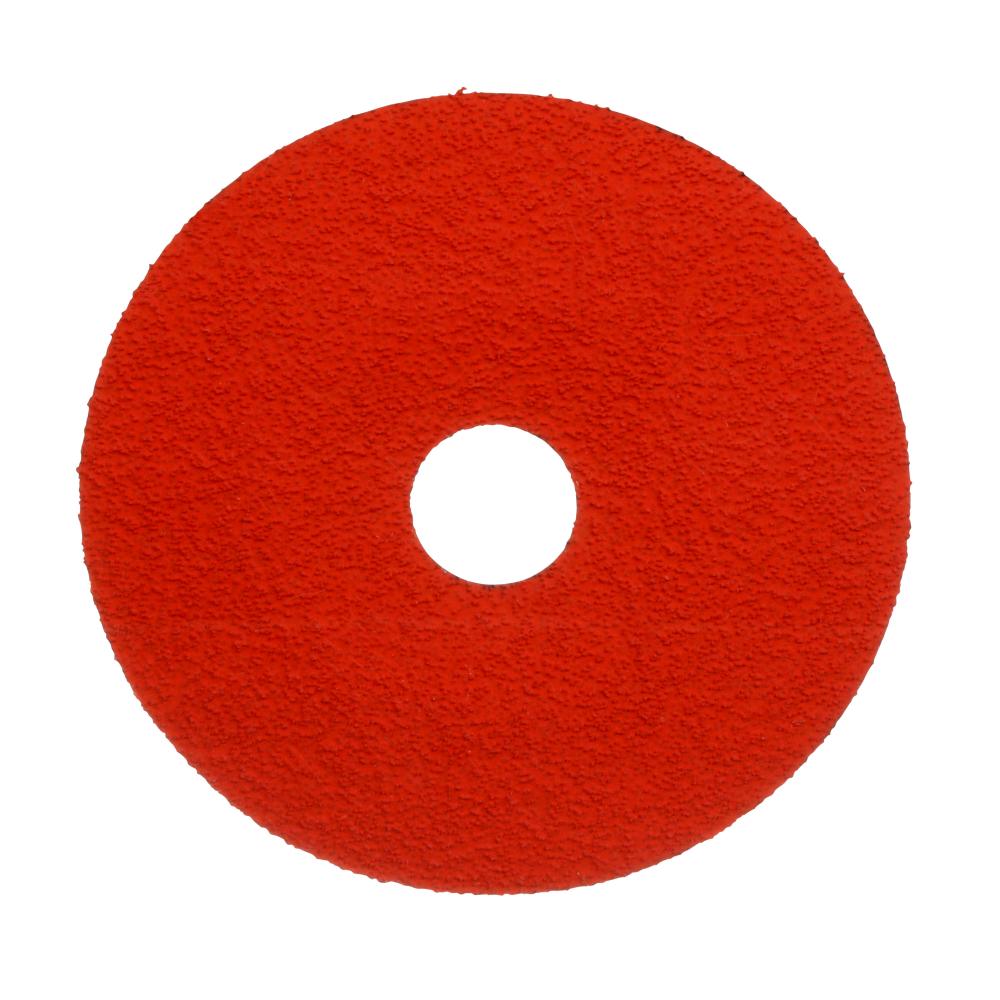

3M™ Fibre Disc, 787C, 60+, 4-1/2 in x 7/8 inItem is usually in stock, but we'll be in touch if there's a problem

by 3M

3M™ Fibre Disc, 787C, 60+, 4-1/2 in x 7/8 inItem is usually in stock, but we'll be in touch if there's a problem

by 3M

Call for Price

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

3M™ Fibre Disc, 787C, 60+, 4-1/2 in x 7/8 inItem is usually in stock, but we'll be in touch if there's a problem

by 3M

Price:

Call for Price

Part Number: 408AF4D

UPC:

Vendor Item Number: 7100099287

Call for Price

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

Technical Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Sanding Discs and Kits

Category Level 4:

Fiber Discs

Abrasive Material:

Precision Shaped Ceramic

Application:

Finishing , Grinding

Attachment Type:

Center Hole

Backing Material:

Fibre

Center Hole Thread Size:

Non Pertinent

Coat Type:

Closed Coat

Color Family:

Orange

For Use On:

Titanium

Grade:

Non Pertinent

Grit:

60+

Hole Configuration:

450E

Maximum Speed:

13300.0 rpm

Product Color:

Orange

Product Form:

Disc

Substrate:

Stainless Steel

Manufactured By:

3M

+

Additional Information

- 3M Precision Shaped Ceramic Grain yields higher cut rates and cooler cut while completing more parts per disc than conventional fibre discs

- Grinding aid minimizes grinding temperatures for heat-sensitive alloys

- Rapidly cuts hard-to-grind metals like stainless steel and high nickel alloys

- Stiff fiber backing and strong resin bond provide durability and tear-resistance

- To be used with right angle grinders

Product Overview

Engineered for ultra-rapid cut, 3M™ Fibre Disc 787C features 3M Precision Shaped Ceramic Grain. With its outstanding cut, durability and ease of use, this disc offers a step up in performance over conventional fibre discs. Constructed with a grinding aid, it is an excellent choice for weld removal, blending and finish refinement on stainless steel and high nickel alloys.3M Fibre Disc 787C contains the exact amount of 3M Precision Shaped Ceramic Grain (PSG) you need to optimize the balance of speed and longevity for challenging applications from grinding to deburring. Moreover, to keep the disc and workpiece cool, a grinding aid is incorporated, further prolonging disc life. Disc construction includes a stiff fiber backing and strong resin bond that provide durability and tear-resistance, which along with abrasive grain enables operators to complete more parts per disc and requires fewer disc changes. To accomplish this level of performance, 3M engineers apply proprietary microreplication technology to create precise triangular structures of 3M Ceramic Abrasive Grain and then electrostatically orient them on the backing to form sharp peaks. These ultra-sharp peaks slice cleanly through metal and continuously self-sharpen as the points break off rather than gouging or 'plowing' as conventional abrasives do. To suit many different project needs, we offer these discs in a range of sizes and a variety of attachment styles. Larger sized discs have a 2.22 cm center hole and require the use of a 3M Disc Pad Face Plate and Hub, which are attached to a right angle grinder with a disc retainer nut (all sold separately). GL and TN quick change attachments are an option for 11.43 cm to 17.78 cm discs. Smaller sized quick change Roloc Discs are also available (sold separately) and provide reliable attachment to the tool and easy disc changes between applications. Please select discs with the attachment design made for your system. Fibre discs are heavy-duty abrasives that feature a tough, stiff backing made from vulcanized fibre that resist wear and can handle tough grinding applications. For optimal performance, the disc should be used with a face plate of the appropriate density - a lighter density face plate for lighter weight grinding applications and a harder density face plate for more heavyweight grinding applications. Using the correct face plate for the application ensures that the abrasive mineral will re-sharpen, maximizing the life of the abrasive.